Pressurisation Units 101

The Comprehensive Guide to Enhancing Efficiency & Safety in Pressurised Heating and Cooling Systems

Your home... a beacon of warmth in the winter and a cool haven in the summer, thanks to the silent guardians hidden within your walls. No, not superheroes... Something a bit more tangible and real – Pressurisation Units.

These unsung heroes work tirelessly to ensure your heating and cooling systems run smoothly, but like a duck gliding on a pond, you only see the calm, not the frantic paddling beneath the surface.

Let's journey to uncover the secrets of pressurisation; we'll gently peel back the layers to understand how these units work, their advantages, and where they fit into the grand scheme of modern heating and cooling systems. Join us on an insightful journey into the world where maintaining the right pressure is essential for smooth operation. Let's embark on this exploration and uncover why pressurisation units are key players in the background of effective pressure maintenance & monitoring.

An Introduction to Pressurisation Units

Pressurisation units are foundational to heating and cooling systems, ensuring that the pressure levels remain optimal for both residential and industrial environments. They are a marked improvement over traditional open systems that struggle with corrosion and inefficiency. These units are especially crucial in applications where it is necessary to maintain the purity of the mains water supply and safeguard it against any contamination from the water within a sealed system. They are indispensable when the mains water pressure is insufficient to fill and sustain the sealed system's integrity, which is essential for its proper function and longevity.

By addressing these specific needs, pressurisation units increase system efficiency and reliability, making them a key component in modern heating and cooling solutions.

So, How Do Pressurisation Units Actually Work?

Pressurisation units essentially maintain a consistent system pressure, which is crucial for preventing cavitation and system damage that could affect the boiler's running requirements. These units come equipped with peripheral pumps that automatically activate to boost pressure and ensure the fluid flow remains constant. This is essential for the system's efficiency. Additionally, the enclosed design of these units helps prevent air contamination and oxidisation, which ultimately reduces maintenance costs and enhances the system's reliability.

However, not all pressurisation units are born equal and use peripheral pumps; some use piston pumps, and the Flamco G4 is even pumpless!

What is Cavitation?

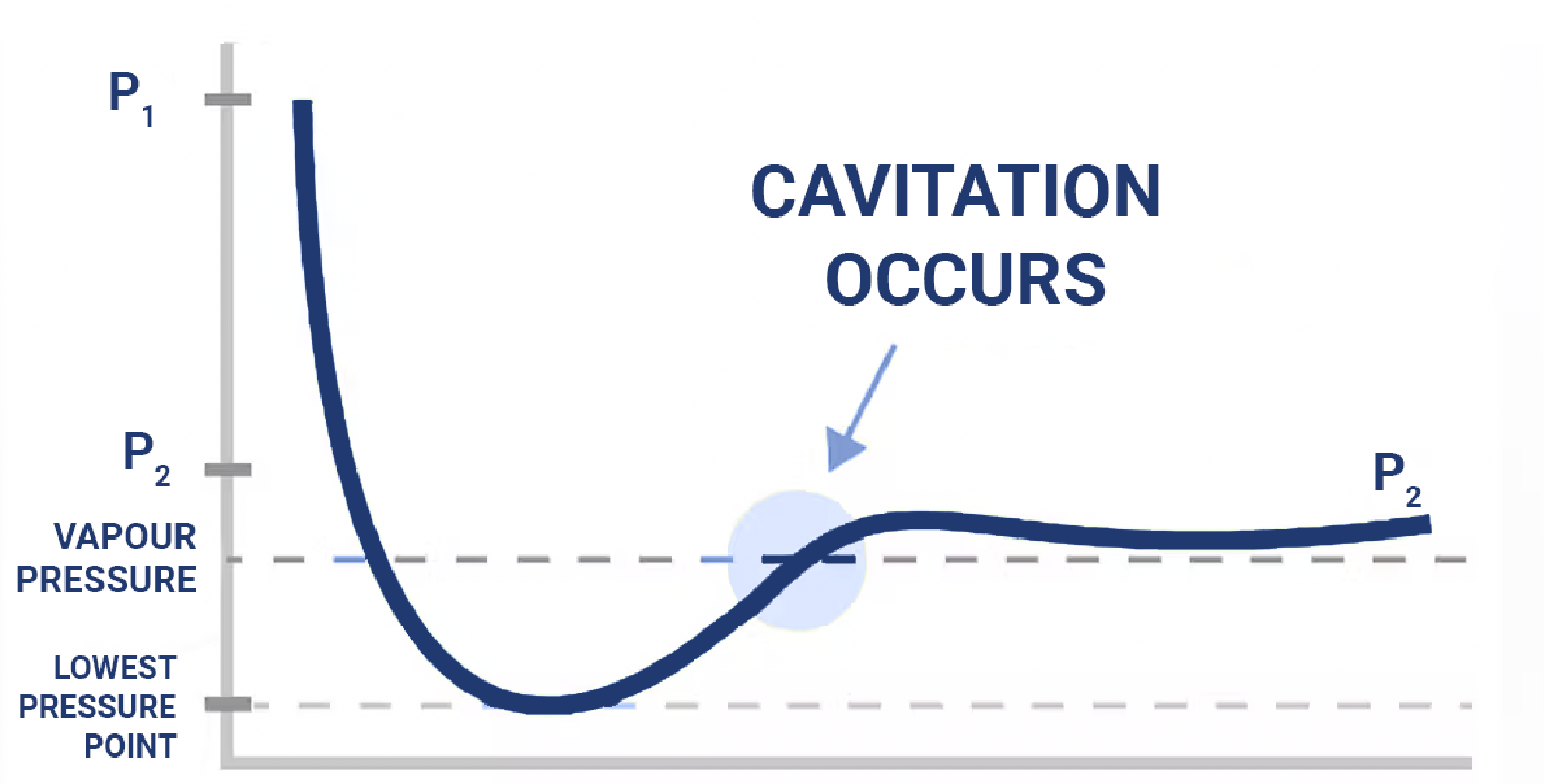

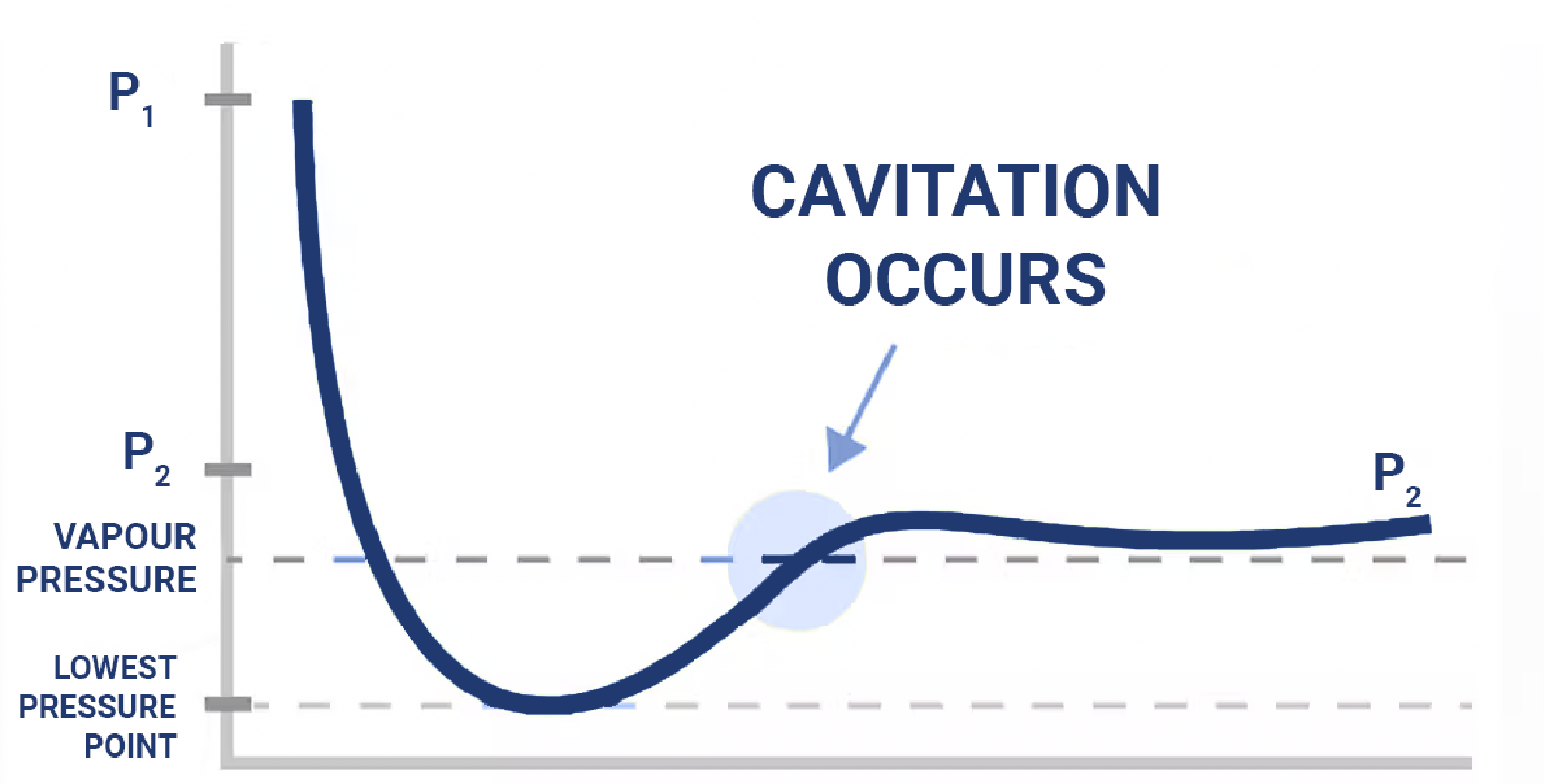

Pressure Dynamics

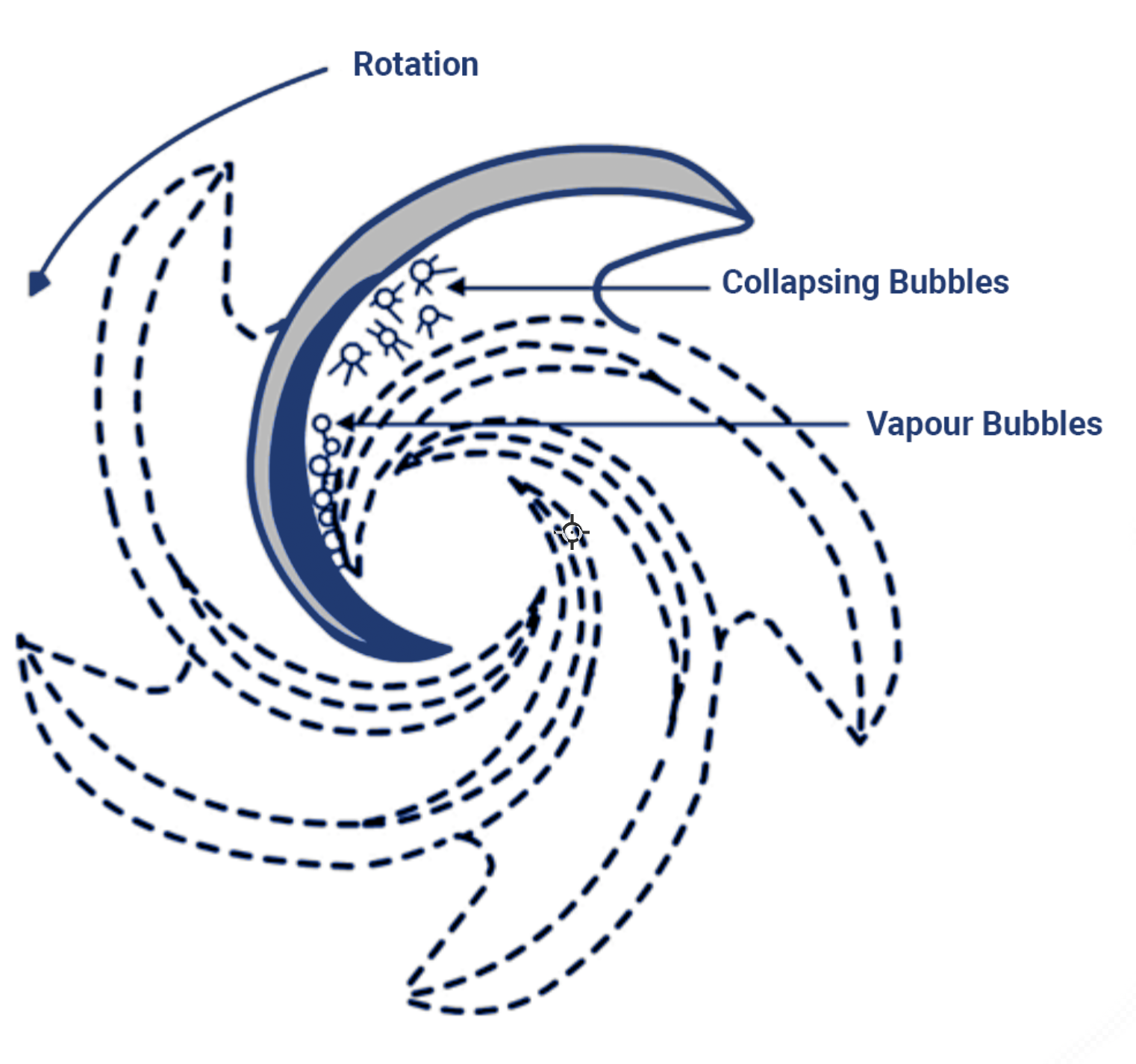

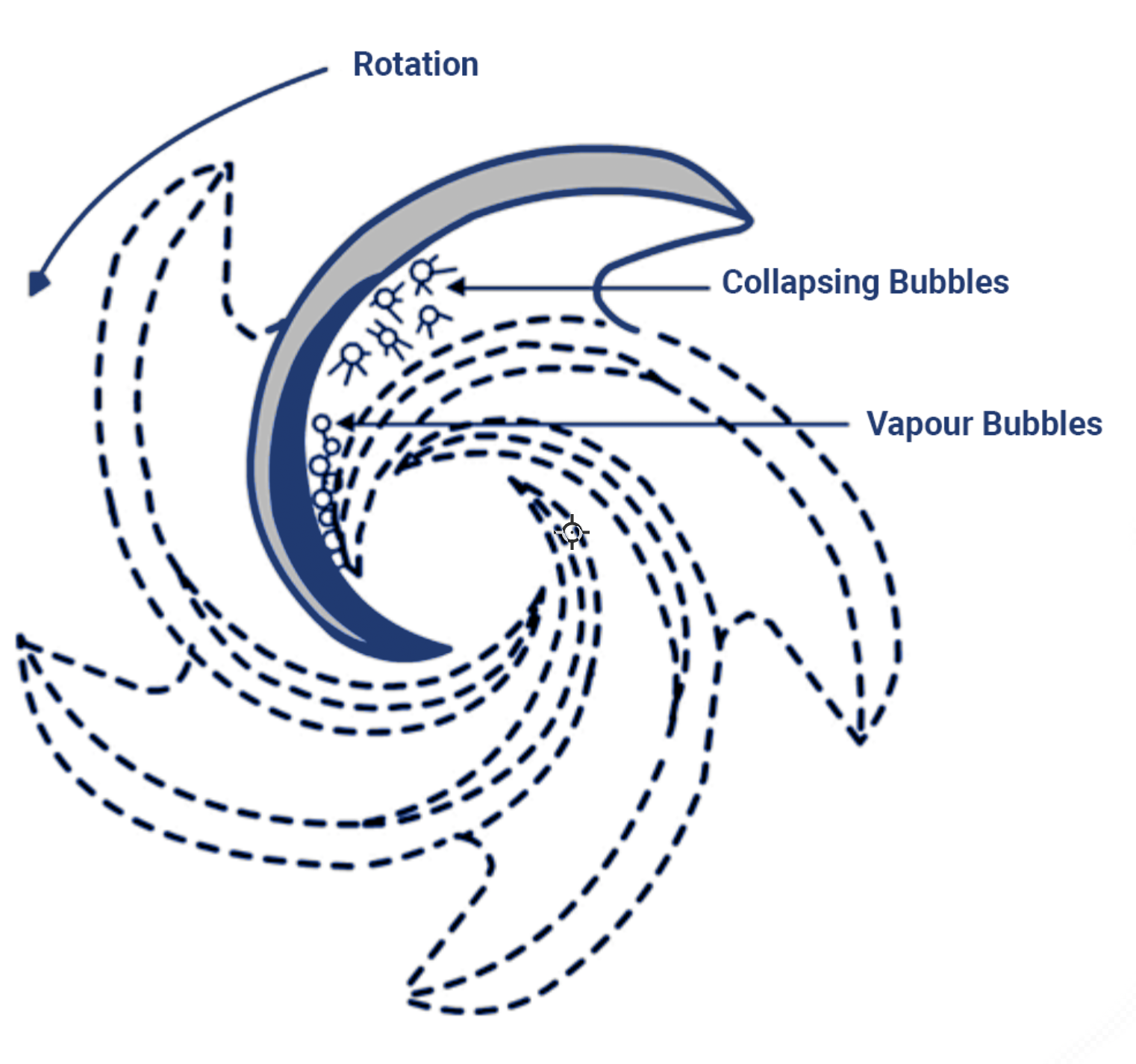

The pressure profile can be quite the character in a pumping system, influenced by various elements like throughput rate, head pressure, and friction losses. It's a bit of a journey – in a centrifugal pump, pressure takes a drop at the impeller's eye; this pressure drop is usually what leads to cavitation – only to rise again within its vanes.

Centrifugal vs. Positive Displacement Pumps

Compared to a positive displacement pump, here it's a different story. The fluid's pressure experiences a drop when drawn into the chamber and then gets a boost as it's expelled. It’s a bit like a 'push-me-pull-you' situation.

The Drama of Pressure and Cavitation

Now, here's where things get more dramatic. If the fluid pressure ever dips below its vapour pressure, it starts boiling and forms vapour bubbles, causing a bit of a stir in the pump. This leads to lower throughput and more noise. When these bubbles venture into areas of higher pressure, they implode – it's a bit like bubble fireworks! This implosion can be quite harmful to the pump, contributing to erosion.

Achieving System Harmony

Getting the match right between the pump, the fluid, and the system is important to keep the peace in your pumping system. It's a delicate balancing act, so a good chat with your pump supplier, such as ourselves, can be quite enlightening, helping you avoid any unwanted drama in your system.

Vapour Cavitation Diagram

Cavitation in Action

Types and Applications of Pressurisation Units

Range of Pressurisation Units

Space-Saving Solutions and Versatile Designs

Pressurisation units are super versatile, catering to various needs and spaces. You'll find them in different sizes and styles, much like choosing the right outfit for an occasion.

They come as wall-mounted units, perfect for when space is at a premium, or floor-standing models for those with more room to spare. Then there are the dual-system units, like the Swiss Army knives of pressurisation units, which are adaptable and ready for diverse system sizes.

Premium and Specialised Options

For the larger, more demanding systems, dynamic units step in. They're the premium of the bunch, activating pumps based on water demand – like turning on the lights only when you need them, ensuring efficiency and savvy operation. And for those who like a bit of extra flair, specialised units come with bells and whistles like vacuum degassers or automatic chemical dosing.

Benefits and Design Innovations

Modern pressurisation units bring a suite of improvements over traditional systems. They're designed to be compact, easily fitting into spaces where older, larger units might have struggled. Energy efficiency is key, allowing them to operate more economically and environmentally friendly.

Additionally, these units have a strong resistance to corrosion, thanks to their advanced designs and updated materials. This resilience means they need less maintenance, like having a dependable car that rarely needs a trip to the mechanic. The improved sealing and integration with smart building systems further reduce the upkeep and align them with contemporary technology trends.

In essence, these modern units significantly boost the reliability of heating and cooling systems. They address common issues like corrosion and are thoughtfully designed for efficient space utilisation, making them a smart choice for new installations and system upgrades.

Latest Pressurisation Units

Installation, Maintenance, and Safety

Proper installation and consistent maintenance are key for pressurisation units to perform at their best. Think of it like caring for a garden – regular attention ensures flourishing results. This includes routine checks such as draining expansion vessels and keeping an eye on air charges, akin to weeding and watering the garden to keep it healthy.

Moreover, these units aren't just about performance; they're also designed with a keen eye on safety. Equipped with safety circuits and emergency protocols, they adhere to stringent safety standards. This ensures the system operates efficiently and safely, providing peace of mind and optimal functionality. Regular maintenance and adherence to safety protocols are the cornerstones of ensuring these units serve their purpose effectively and safely. That’s not to mention the financial benefit of maintenance – Research consistently demonstrates that every quid (£1) invested in preventive or predictive maintenance saves up to a fiver (£5) on unforeseen expenses.

How Cavitation Occurs

What Are The Symptoms of Cavitation?

Modern pressurisation units bring a suite of improvements over traditional systems. They're designed to be compact, easily fitting into spaces where older, larger units might have struggled. Energy efficiency is key, allowing them to operate more economically and environmentally friendly.

Additionally, these units have a strong resistance to corrosion, thanks to their advanced designs and updated materials. This resilience means they need less maintenance, like having a dependable car that rarely needs a trip to the mechanic. The improved sealing and integration with smart building systems further reduce the upkeep and align them with contemporary technology trends.

In essence, these modern units significantly boost the reliability of heating and cooling systems. They address common issues like corrosion and are thoughtfully designed for efficient space utilisation, making them a smart choice for new installations and system upgrades.

Choosing the Right Unit

Selecting the right pressurisation unit for your system is like finding the perfect pair of shoes – it must fit well and be suitable for the purpose. Understanding your system's static head and system capacity is crucial – Ensuring the unit's capabilities align neatly with your system's needs.

Considerations include the size of the unit – you wouldn't want something too big or too small, just as you'd pick a shoe that fits just right. Efficiency is another key factor, like choosing comfortable shoes for long walks. Then, there are the specific features – like opting for waterproof shoes for rainy days- you might need particular features in your pressurisation unit to suit specific system requirements.

Getting this match right ensures your system runs smoothly, efficiently, and effectively, just as a well-chosen pair of shoes can make your day more comfortable and productive - Unfortunately, we're not good with shoes... but our team can help you choose the correct pressurisation unit if you’re unsure.

Pressurisation Unit FAQs

Do I really need a pressure tank?

Indeed, particularly in the context of pressurised water systems, pressure tanks play a pivotal role in ensuring consistent water pressure and in significantly extending the lifespan of the well pump. By storing water under pressure, these tanks minimise the frequency with which the pump has to cycle on and off, thereby preserving its longevity. The absence of a pressure tank places additional stress on the pressure switch/controller, potentially precipitating its premature failure. This aspect becomes critically important in systems equipped with appliances like showers or toilets, where the pump may not consistently operate at full capacity.

Furthermore, it's essential to acknowledge that water undergoes expansion with temperature fluctuations. The water reaches its maximum density at 4°C. As the temperature drops from 4°C to the freezing point, water expands by approximately 9% (or about 1/10th) by volume. Conversely, when the temperature rises from 4°C towards boiling at 100°C, water expands by roughly 4% (or about 1/25th) by volume, becoming significantly less dense in the process. Consequently, hot water and heating systems must incorporate mechanisms to accommodate this thermal expansion. Moreover, a fail-safe system is imperative to address situations where the primary expansion accommodation mechanism fails, ensuring the system's safety and integrity. This dual approach to managing thermal expansion and safeguarding against system failures underscores the comprehensive design considerations necessary for efficient and reliable pressurised water systems.

What is the difference between “Pressurized” and “Pressurised”?

The terms "pressurized" and "pressurised" essentially mean the same thing, referring to the state of being under pressure. The difference is primarily in the spelling, with "pressurized" being from across the pond with American English and "pressurised" being our jolly tea-loving British English.

Fun Fact: You may notice Americans used a lot more Z’s and English S’; this is due to American English using Latin language rules and English using French language rules.

What is cold fill pressure?

Cold fill pressure is the pressure in a heating system, usually a boiler, when the system is cold. This pressure is crucial in ensuring the system operates effectively when it heats up. It is the baseline pressure required for the heating system to function efficiently. Therefore, maintaining the correct cold fill pressure is essential to enable the heating system to operate optimally.

What is the operating pressure for LTHW (Low Temperature Hot Water) systems?

LTHW systems operate at varying pressures and temperatures below 250°F and pressures below 160 PSIG. Modern systems use lower temperatures, such as 80/60°C or even 50/30°C for flow and return temperatures. These lower temperatures can be more efficient, especially when using renewable energy sources.

How do you size a pressurisation unit?

When sizing a pressurisation unit, you need to consider multiple factors. These include:

- The pump's flow rate.

- Your water system's demands.

- System safety valves.

- Flow and return temperatures.

For example, a typical private water supply pump with a flow rate of 5 to 10 gallons per minute would require a diaphragm or bladder pressure tank size four times the flow rate. If you have a low-yield well system, there are special considerations, too.

Our Conclusion

Pressurisation units are an important part of modern heating and cooling systems. They are crucial in maintaining optimal pressure levels and enhancing the system's efficiency. These units are designed to be compact and energy-efficient and come with advanced features that make them superior to traditional systems. To ensure optimal performance and longevity, it is essential to understand their functionality, types, and maintenance needs.